Brewing - Golden Mild Ale

Yeast prep - March 21, 2020

Prepared a 2L starter with yeast saved from 2nd overbuilt starter (Ordinary Bitter, March 2nd). Reserved 500ml for future starter, gave 400ml to a friend and pitched remaining 1L to Mild Ale.

Golden Mild Ale Brewday - March 22, 2020

44L (Primary) | 1.039 OG | 16 IBU | 5 SRM

Part 1 - Setup

- Grist -

81.1% | 6kg Canada Malting Superior Pale Ale Malt (3.1L)

13.5% | 1kg Weyermann Munich Type II (8L)

05.4% | 400g Simpsons Crystal Light (34L)

- Hops -

|| Kettle ||

|| Kettle ||

30g East Kent Golding (4.5% AA) @ 60 minutes

30g East Kent Golding (4.5% AA) @ 20 minutes

30g East Kent Golding (4.5% AA) @ 5 minutes

30g East Kent Golding (4.5% AA) @ 20 minutes

30g East Kent Golding (4.5% AA) @ 5 minutes

- Water -

56L treated with 1 campden tab to remove chloramine

56L treated with 1 campden tab to remove chloramine

Source Profile (mg/l):

Ca+2 = 8.7

Mg+2 = 2.1

Na+ = 18.4

Cl- = 6.7

SO4-2 = 27

Alkalinity (ppm as CaC03) = 32.5

pH = 9.4

Mg+2 = 2.1

Na+ = 18.4

Cl- = 6.7

SO4-2 = 27

Alkalinity (ppm as CaC03) = 32.5

pH = 9.4

|| Salts & Acid ||

Mash - 2ml (88%) Lactic Acid, 6g Calcium Chloride, 6g Calcium Sulfate

Mash - 2ml (88%) Lactic Acid, 6g Calcium Chloride, 6g Calcium Sulfate

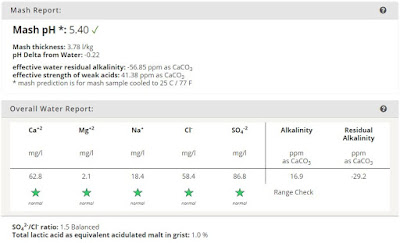

Resulting Profile (mg/l) :

Ca+2 = 62.8

Mg+2 = 2.1

Na+ = 18.4

Cl- = 58.4

SO4-2 = 86.8

Alkalinity (ppm as CaC03) = 16.9

Residual Alkalinity (ppm as CaC03) = -29.2

Brewer's Friend Mash Report

Ca+2 = 62.8

Mg+2 = 2.1

Na+ = 18.4

Cl- = 58.4

SO4-2 = 86.8

Alkalinity (ppm as CaC03) = 16.9

Residual Alkalinity (ppm as CaC03) = -29.2

Brewer's Friend Mash Report

Part 2 - Mash

Mash salts added directly to the milled to grist

Lactic acid added to half the brewing liquor (28L)

Mashed in @ 73C/162F

Target mash pH 5.40 (calculated @ 25C)

Mashed @ 65.5C/152F

Mashed in @ 73C/162F

Target mash pH 5.40 (calculated @ 25C)

Mashed @ 65.5C/152F

After 60 minutes, vorlauf and collected 1st runnings

At the start of the boil added 1st hop addition (60 minutes)

With 20 minutes remaining, added 2nd hop addition

With 5 minutes remaining, added 3rd hop addition, whirlfloc

At flame-out, added hop filter and immersion chiller

With 5 minutes remaining, added 3rd hop addition, whirlfloc

At flame-out, added hop filter and immersion chiller

Chilled wort and transferred to fermenter

|

| 43.5L Transferred to Primary |

Day 0 - 16:00 - Pitched 1L (500ml/carboy) @ 14C, carboys placed inside the fermentation freezer with heat lamp and warmed to 20C

Day 1 - 16:00 - Temperature steady at 20C, active fermentation

Day 3 - 10:00 - Increased temperature to 21C

Day 6 - 21:00 - Removed heat controller. Lid left shut to try and retain heat

Day 12 - 11:00 - Moved carboys from fermentation chamber to a colder spot to further condition

Day 18 - 15:00 - Racked both carboys to keg. FG measures 1.015, 62% Atten for an ABV of 3.1%

Day 20 - 15:00 - There is something very wrong with this beer. Having split off my starter 3-ways, I believe I may have inadvertently and significantly under-pitched. Combine this with the fact that I did not aerate the beer, the resulting conditions were likely too stressful for the yeast. Additionally, since I brewed both APA and IPA very closely to the Mild, my standard heating solution was not available. For the Mild, I improvised and used a incandescent lamp (as the heat source) in conjunction with a temperature controller. Perhaps the heat cycles were too strong? Maybe my temperature controller probe was not well placed and therefore provided incorrect temperature read-outs? What every the case, I believe the specific flaw is excessive ester formation, specifically Isoamyl Acetate which can be directly attributed to poor temperature control (too hot) and poor yeast conditions (under-pitch). In short, it smells and tastes like pears (but not in a good way). Some online brewing literature suggests the effect may decrease with aging. I plan to give the beer a couple more weeks in the kegs (at ambient) to see if it's heading the right direction otherwise I'll be dumping it down the drain.

Day 1 - 16:00 - Temperature steady at 20C, active fermentation

|

| +24hrs @ 20C |

Day 3 - 10:00 - Increased temperature to 21C

Day 6 - 21:00 - Removed heat controller. Lid left shut to try and retain heat

Day 12 - 11:00 - Moved carboys from fermentation chamber to a colder spot to further condition

Day 18 - 15:00 - Racked both carboys to keg. FG measures 1.015, 62% Atten for an ABV of 3.1%

|

| 1.015 (Temperature Corrected) |

Comments

Post a Comment